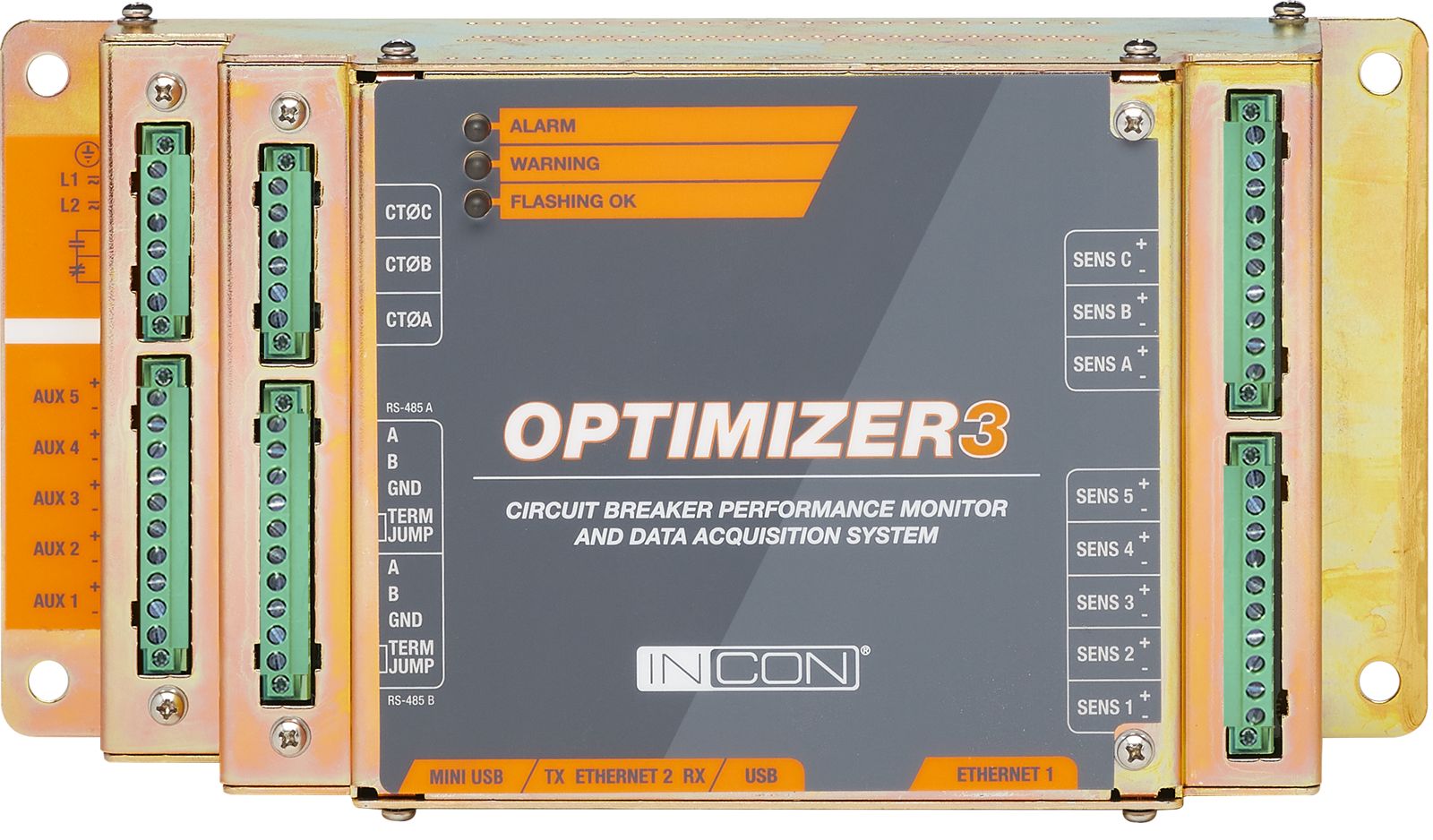

INCON Optimizer3

The INCON® Optimizer3 Circuit Breaker Monitor delivers advanced automated reporting of all critical circuit breaker diagnostics to ensure uptime and facilitate predictive maintenance. The Optimizer3 is ideal for high-voltage, live or dead-tank, oil, vacuum or gas circuit breakers.

EXTENDING THE SERVICE LIFE OF CRITICAL ASSETS

Electric utility companies rely on circuit breakers to protect their critical assets and ensure reliability of the electric grid. However, many circuit breaker systems in use today are aging. Installing, replacing, or upgrading, these systems is not only complex but also costly. Learn how some utilities are combating aging infrastructure with advanced monitoring systems to extend the service life of critical assets and implement predictive maintenance strategies.

EXTEND THE LIFE OF YOUR CIRCUIT BREAKER

The early problem detection and automated system performance evaluation capabilities of the Optimizer3 help improve the efficiency, service life, and reliability of electric utility systems.

KEY ADVANTAGES

24/7 REAL-TIME ANALYSIS

The web-based software provides monitoring data on both the mechanical and electrical performance of a circuit breaker, delivering trending analysis that predicts the date of future service.

CONDITION BASED MAINTENANCE

Armed with a high degree of circuit breaker performance insight from the Optimizer3, utilities can deploy maintenance with intelligence and only as needed – limiting truck roles, speeding reaction time, and lowering overall maintenance costs.

BREAKER TIMING

In the milliseconds it takes for a circuit breaker to trip, the Optimizer3 collects a full battery of timing data including opening (trip) time, clearing time, arc duration, and opening/closing travel times and velocities are automatically analyzed to provide a full assessment of the circuit breaker’s health.

SF6 REPORTING

The Optimizer3 aids in the mandatory compliance reporting required by the EPA, resources boards, and other regulatory agencies by monitoring for SF6 gas leaks and related indicators and automatically reporting any fugitive emissions.

COMPLETE CIRCUIT BREAKER DIAGNOSTICS

With 8 sensor inputs, 5 timing inputs, and an onboard ambient temperature sensor and supply voltage monitor, the Optimzer3 and its array of sensors deliver a complete diagnostics report of a circuit breaker’s performance. Utility technicians are empowered with the data to repair a small issue before it causes a substantial failure that may require equipment replacement or even an entire overhaul of a high-cost asset.

VOLTAGE & CURRENT MONITORING

Real-time voltage and current are measured with an array of high-accuracy, loop-powered voltage and current transducers. Applications include motor current, station battery voltage, heater current, and compressor run-time.

SF6 GAS MONITORING

SF6 gas density, pressure, and dew point sensors and fill point adapters aid in the mandatory compliance reporting required by the EPA, resources boards, and other regulatory agencies by monitoring for SF6 gas leaks and related indicators and automatically reporting any fugitive emissions.

SF6 GAS HUMIDITY ABSORBER

The SF6 gas humidity absorber can passively absorb up to 40 mL of water from SF6 gas, saving major expense vs. standard circuit breaker moisture removal. The corrosion-resistant absorber is easily connected to a circuit breaker's SF6 gas port.

TANK HEATER MONITORING

The Optimizer3 monitors the tank heater’s supply current using a universal power status monitor. If one or more of the heater elements fails, the Optimizer3 will assert a heater alarm.

Need help determining which products you need?

Call us at 800-866-5353 and we can help.