CELLGUARD™ Wired

The CELLGUARD wired Battery Monitoring System (BMS) delivers economical, yet highly accurate and reliable remote health analysis of stationary batteries in applications with high electromagnetic noise. Battery operators are provided with continuous 24/7 monitoring of key battery performance indicators to help enable proactive maintenance, ensure battery performance, and deliver uninterrupted power when it matters the most.

ENSURE UPTIME WITH 24/7 MONITORING

Utility personnel are provided with continuous 24/7 monitoring of key battery performance indicators to help enable proactive maintenance, ensure battery performance, and deliver uninterrupted uptime when it matters the most.

KEY ADVANTAGES

STATE OF HEALTH

The BMS helps analyze data trends related to battery state of health, simplifying the detection of potential issues for operators to optimize battery usage.

INTERNAL RESISTANCE TESTING AND PERFORMANCE TRENDING

The BMS tests a given battery’s internal resistance at a pre-determined interval. The results are then collected and presented as a trend providing the user with genuine DC power plant performance insight.

DISCHARGE EVENTS

Battery discharge events are recorded automatically (including battery voltage, string voltage, discharge current and discharge capacity).

PARAMETER AND ALARM THRESHOLDS

The user can set / modify many measurement parameters and thresholds either locally or remotely. The system invokes a permission hierarchy to manage administrative access.

SOLID HARDWARE

The CELLGUARD Wired Battery Monitoring System ideal for all mission-critical DC power plants including UPS, data center, rail / subway, airport, telco, utility power generation, utility substation, and manufacturing, as well as fire and safety systems.

BATTERY SENSORS

One battery sensor per battery is capable of monitoring internal resistance, voltage, and temperature, delivering a comprehensive battery state of health analysis.

BASE COORDINATOR UNIT

The base coordinator unit (BCU) records critical performance elements including alarms and discharge events. Alarm parameters and thresholds are managed through the BCU which also delivers real-time system data through the web-based UNITE™ Battery Asset Management Software.

The BCU can communicate via RS485, Ethernet, MODBUS/RTU, MODBUS/TCP, and SNMP protocols. Data derived from the BMS is easily integrated into most third-party systems.

STRING SENSOR & CURRENT TRANSDUCER

One string sensor per string, in conjunction with a string current transducer provides monitoring of the string voltage, current, and ambient temperature.

SOFTWARE FEATURES

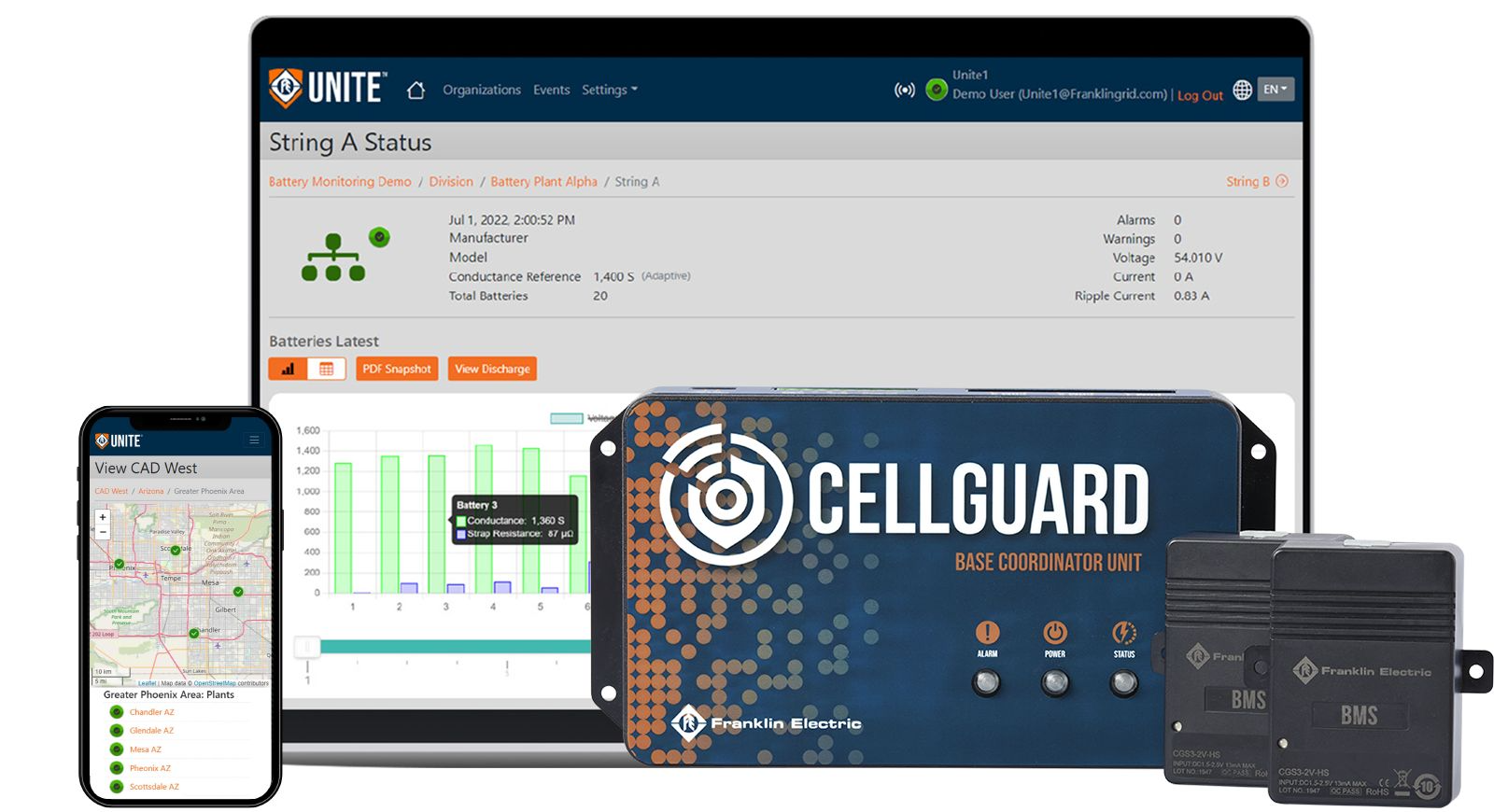

UNITE™ allows you to seamlessly and remotely drill down through your network of battery plants, strings, and individual batteries. Gain access to valuable performance insight data, enable cost-saving condition-based maintenance planning, and simplify your compliance reporting.

SIMPLIFY REPORTING

With a single click, a battery string report PDF can be generated to streamline reporting and compliance requirements. Reports include the latest battery data, a string overview table and graph, battery reference information, battery threshold details, and more.

PLANT MAP VIEW

Visualize your entire plant network geographically in a single map view. Visually confirm the status of all plants and quickly key in on those that may require attention or maintenance.

BATTERY VIEW

Dive into the present and historical performance data of individual batteries within a string. Visualize key battery performance indicators and trending data to pinpoint batteries in need of replacement with accuracy.

DISCHARGE VIEW

UNITE provides a graphical timeline view of every string discharge event for advanced performance analysis and NERC compliance reporting. Discharge data includes start time, end time, voltage, temperature, and current.